Pet food production line

Producing pet food safely and efficiently is possible with Selo's pet food production line. We have been developing advanced production systems for both cat and dog food for many years. We invest in technology and are still innovating the machines every day so that each product meets the highest possible quality standards. With the pet food production line, you can produce the desired amount of wet pet food daily in precise portions.

The production line can be customized to your exact needs and requirements. Whether it's established A-brands or a start-up manufacturer who wants full guidance for a process line. Selo provides it. The machines are designed for sustainable production and the production line is also equipped with advanced safety features to ensure that the pet food produced meets the highest safety standards. Selo is the undisputed market leader in the wet pet food production industry.

From complete pet food production line to specific solution

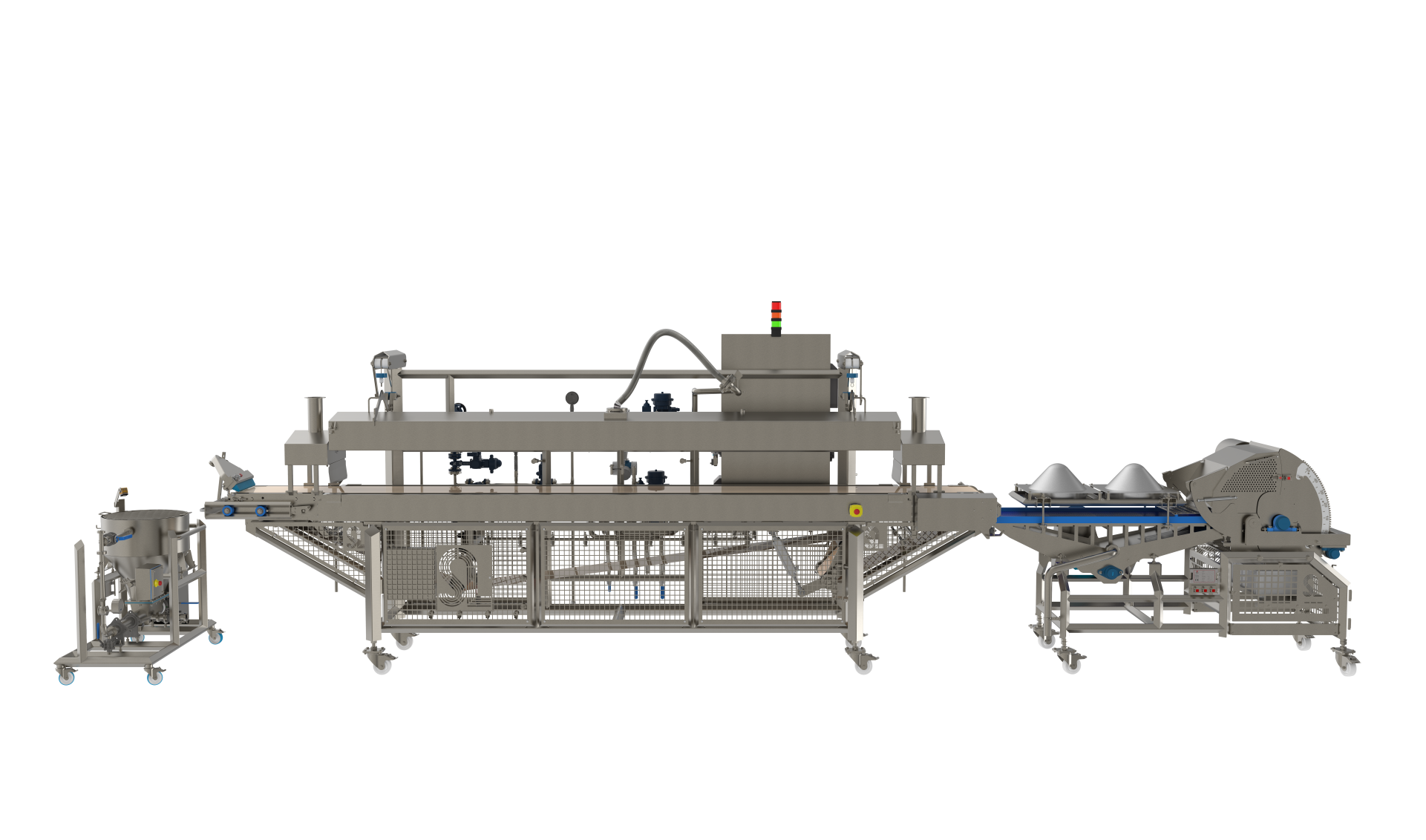

Every pet food production line starts with the consistent quality of the recipe, ingredients and proper process line configuration. We ensure that the process line and production environment are perfectly matched. More than that: we can advise you on the complete production process. From the supply and storage of ingredients, emulsion preparation, optimal cooking process and cooling back to cutting, output to the packaging line and sterilization. Everything for consistent quality and optimum efficiency.

Selo invests heavily in the safety, durability and quality of its products. This means that we strictly adhere to strict quality standards, whether these come from our customers or from regulatory authorities. Our production processes are optimized for food safety, in this case pet food safety.

Advantages of Selo's pet food production line

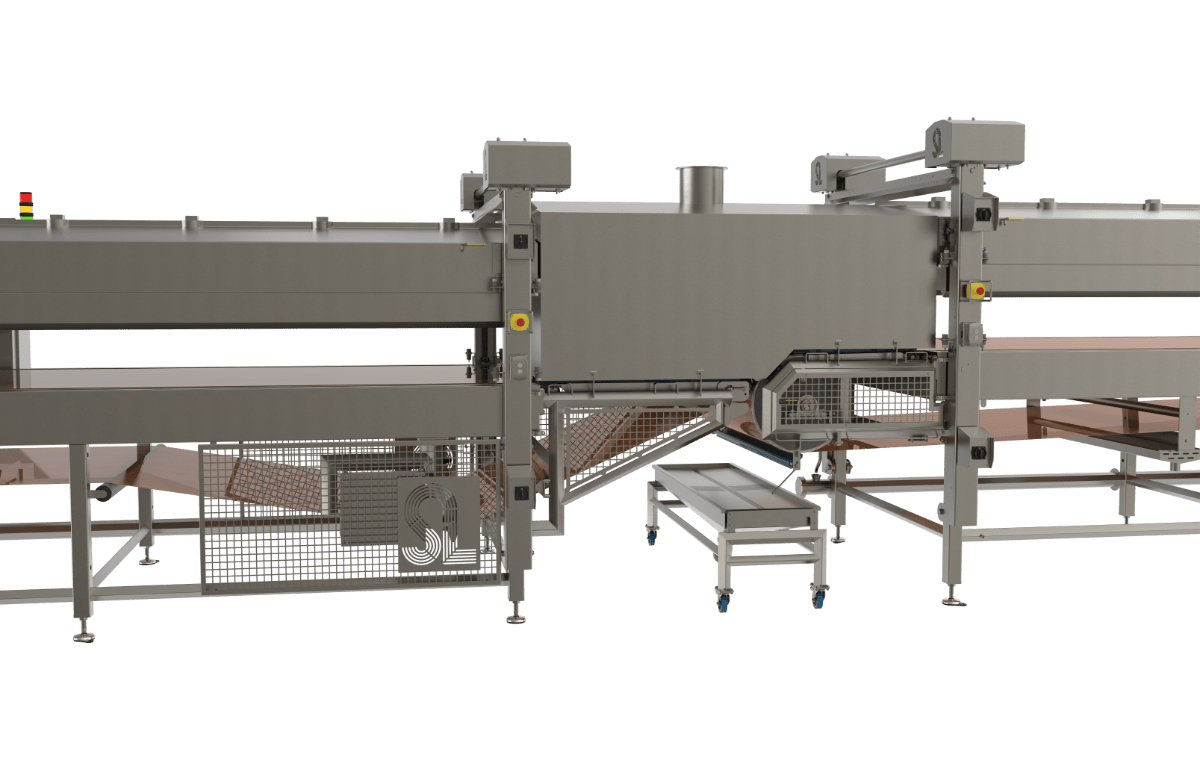

A pet food production line from Selo has several advantages. First, quality is extremely important. Our steam tunnels are of solid quality and comply with all the rules associated with production. A production line must be reliable in all its functionalities and made of materials that can last a long time. Other important advantages are:

- Safety: the production line is tested to perfection for safety, both the pet food and the production process itself must be safe.

- Increased efficiency: the new production line allows your plant to operate more efficiently and effectively, resulting in higher production levels, lower costs and improved profitability.

- Improved portion accuracy: Selo's production line is designed to work with greater precision and speed. Production accuracy is monitored and any discrepancies are detected immediately. This reduces the risk of waste and ultimately increases product efficiency.

- Good connection to the packaging process: these production lines can be connected to different packaging processes.

Cat food manufacturer

EXPERIENCES

Want to know more about our pet food production line? Download the leaflet

Want to learn more about Selo's dog and cat food production line? About applications, specifications and even more advantages, among other things. Then download the leaflet.

Most pet food production lines arise from an output desire: production of cat food in tuna and chicken flavor or dog food in the form of shoarma strips. With that wish, we get to work. Together with the customer, all wishes are collected. Based on technical knowledge and years of experience, our team of engineers converts this information into a detailed production line.

After the approved 2D design is ready, the project team gets to work on both hardware and software. We establish a schedule and order the necessary materials. In our workshop, the production line is carefully assembled, with all components correctly placed and functionally assembled. Once both production and software are extensively tested, the production line is prepared for transport.

Most pet food production lines arise from an output desire: production of cat food in tuna and chicken flavor or dog food in the form of shoarma strips. With that wish, we get to work. Together with the customer, all wishes are collected. Based on technical knowledge and years of experience, our team of engineers converts this information into a detailed production line.

After the approved 2D design is ready, the project team gets to work on both hardware and software. We establish a schedule and order the necessary materials. In our workshop, the production line is carefully assembled, with all components correctly placed and functionally assembled. Once both production and software are extensively tested, the production line is prepared for transport.

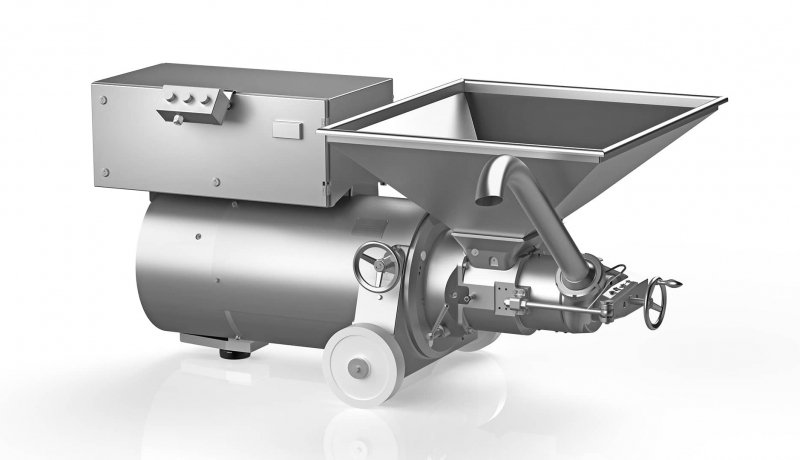

Our pet food production machines

Producing pet food is done with exceptional precision

A healthy and happy dog or cat is every owner's wish. Good nutrition contributes to that. Therefore, it is important for a dog or cat to get the right nutrients. Think high-quality ingredients that have the right balance of proteins, fats, carbohydrates, vitamins and minerals. So as a manufacturer, you will need to ensure that your dog and cat food meets these requirements. Pet food should not only be nutritious, it should also be palatable and appealing to pets. Therefore, it is important for you as a producer to be able to optimize the food each time. In addition, food safety, hygiene, shelf life and sustainability play important roles. With Selo's pet food production line, you as a producer can take all these aspects into account and respond to the needs and expectations of both pets and their owners. At the same time, you continue to grow in the demanding pet food market.

Selo, pet food production line supplier

Selo designs and supplies process systems for the food and pet food industry. We offer an A to Z solution: our projects are completely handled by us from the design phase right through to the commissioning of the systems. We therefore have the disciplines of technology, automation, engineering, assembly, installation and after-sales completely in our own hands. This allows us to provide customized solutions as well as standard solutions.

More information?

Looking for more information about one of our products or have a question or complaint? If so, please contact us using the form below.