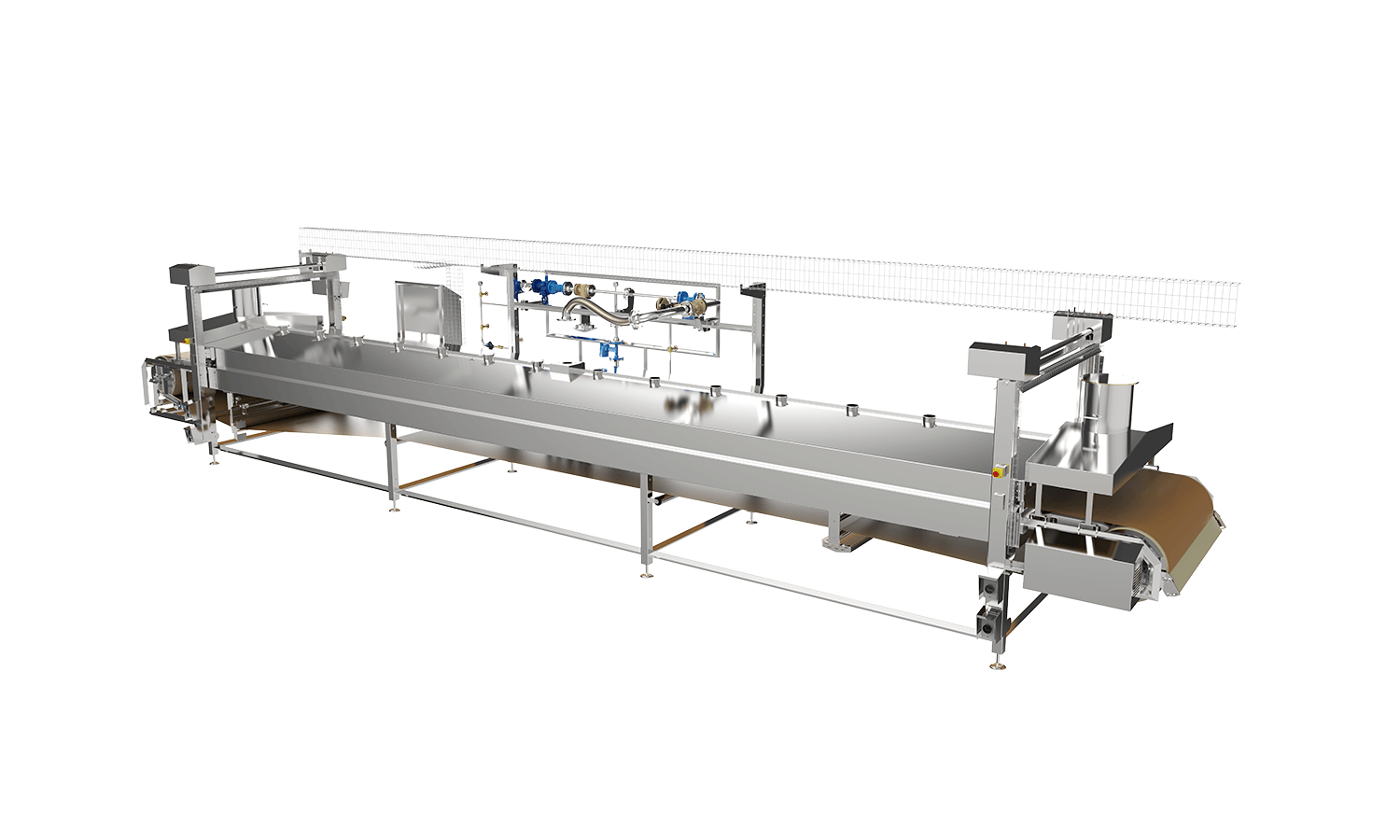

Steam tunnel

In the 1980s, Selo supplied the first steam tunnel for the production of wet animal food, or wet pet food. This innovation caused major changes in the animal food industry. Naturally, the steam tunnel has undergone further developments and is currently the state-of-the-art system for the production of wet pet food. The steam tunnel is used by multinationals of well-known brands, but can also be used by medium to small-sized companies. The equipment is hygienic, efficient, saves on costs and, as such, affordable.

The steam tunnel installation is processing pet food emulsions to chunks. In the steam tunnel the emulsion is cooked with condensing steam. The speed of the processing belt and the steam supply are adjusted to cook until the desired cooking result has been obtained. Exact cooking times are product specific.

A steam tunnel is executed for heating an emulsion from + 5°C up to ± 92°C core temperature. The tunnel mainly exists of two steam chambers (hoods) through which a processing belt is continuously running. By using water locks alongside the tunnel, the containment of the steam is achieved.

The two steam chambers are surrounding the belt. The top hood of the steam tunnel is set down close to the emulsion to ensure that the steam moves correctly between and along the tunnel hood and the emulsion. The top hood can be lifted manually and the height above the emulsion can be adjusted. Heat is transferred to the product in two ways. Steam injected in the top hood condenses on the product surface and heats the emulsion. The steam injected below the processing belt condenses on the belt and heats the emulsion from the bottom.

BENEFITS OF SELO STEAM TUNNELS:

- High production capacity, but also suitable for smaller productions

- Configuring different programs is possible: accurate heating tuned to unique product specifications

- Additional: make use of colour injection systems

- High quality wet pet food that retains flavour and colour

- Selo possesses extensive know-how in the field of animal food production processes

Apart from the steam tunnel used for the production of animal food, Selo can also hygienically and attractively package your animal food products.

Production line supplier

Selo designs and builds process- and packagingsystems for the food manufacturing, animalfeed, pharmaceutical and non-foodindustries. We offer solutions from A to Z: this makes it possible for us to take care of our projects from the design phase until the installation of the systems. We fully master and take care of all technological, automation, engineering, assembly, installation and after-sales disciplines.

Selo provides both custom and standard solutions.