Proces automaten

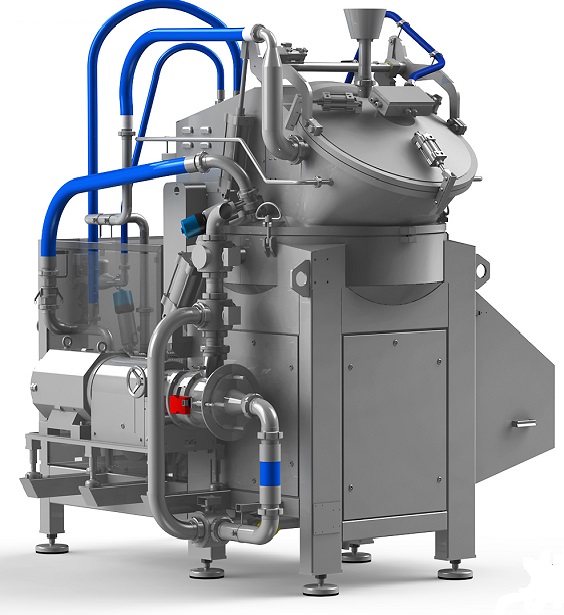

De innovatieve Karl Schnell proces automaten combineren de volgende productiestappen in één machine: voorverkleinen, mengen, fijnverkleinen en homogeniseren, en zorgen daardoor voor een machine die het hele proces kan uitvoeren op een minimaal vloeroppervlak.

De proces automaten worden ingezet bij de productie van soep, saus, jus, ketchup en mayonaise, vis en paté en eveneens voor de bereiding van additieven en specerijen voor de worst-, petfood- en kaasproductie.

VOORDELEN KARL SCHNELL PROCES AUTOMATEN:

- Dankzij de locatie, het ontwerp en het type voorsnijmes wordt een perfect meng effect bereikt al tijdens het voorsnijden

- Emulgeren door middel van een apart snijsysteem

- Via een recirculatiesysteem kan het product meermaals uit de emulgator in de hopper worden gepompt en een hogere fijnheid bereiken

- Meerdere proces stappen in één machine

Leverancier

In de meer dan 70 jaar dat het bedrijf bestaat, is de naam Karl Schnell uitgegroeid tot een internationaal erkend begrip in de voedingsmiddelenindustrie. Het staat voor een Duits machinebouw bedrijf, waarbij volledig ontwikkelde technologie wordt gecombineerd met constante innovatie.

De basis hiervoor is de ontwikkeling van economische, kwalitatieve en toepassingsgerichte machines en systemen. In de geschiedenis van het bedrijf zijn er veel nieuwe machines ontwikkeld die de industriële verwerking van levensmiddelen aanzienlijk beïnvloed hebben.