Vacuüm vulpompen

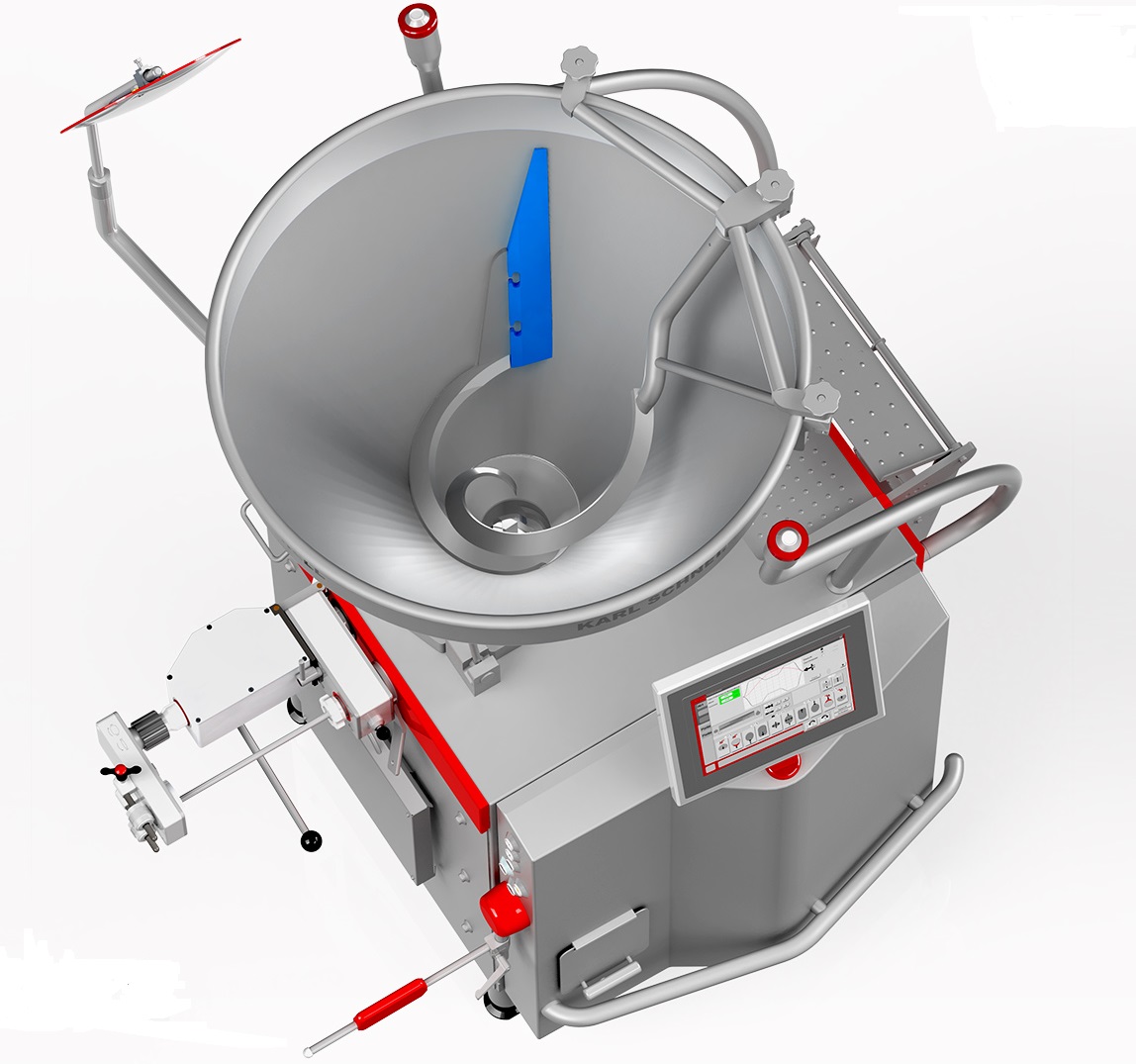

Selo levert Karl Schnell vacuüm vulpompen met een unieke pompset voor een perfecte afvulling. De pompen zijn uit te breiden met diverse voorzetapparatuur, zodat het vul- en productieproces geheel naar wens ingericht kan worden. De slijtvaste pompset en het korte producttransport, voorkomt dat de lucht ingesloten wordt tijdens het afvullen. Hierdoor raakt het product niet beschadigd en blijft de kwaliteit behouden.

Vacuüm vulpompen onttrekken lucht aan het product, waardoor het product langer vers en dus langer houdbaar blijft. Producten die gevuld worden met een vleesmengel (bijvoorbeeld kunstdarmen die gevuld worden met vleesdeeg), hebben er baat bij wanneer dit vacuüm gebeurt. De vacuüm vulpompen worden ook ingezet bij de productie van kaas.

Voordelen Karl Schnell vacuüm vulpompen:

- Nauwkeurige en productsparende behandeling

- Vacumeren tijdens het gehele vulproces

- Massief en vervaardigd van verschillende hoogwaardige roestvrijstaal soorten

- Hygiënisch, eenvoudig te reinigen

Naast vacuüm pompen, levert Selo ook ander vulsystemen en machines. Door de nieuwste technologieën op het gebied van voedselbewerking en verpakkingen te volgen en zelf innovaties te creëren, zijn wij in staat uw gehele productieproces efficiënt en kostenbesparend in te richten. Wij denken graag vanaf het begin tot eind met u mee!

Leverancier

In de meer dan 70 jaar dat het bedrijf bestaat, is de naam Karl Schnell uitgegroeid tot een internationaal erkend begrip in de voedingsmiddelenindustrie. Het staat voor een Duits machinebouw bedrijf, waarbij volledig ontwikkelde technologie wordt gecombineerd met constante innovatie.

De basis hiervoor is de ontwikkeling van economische, kwalitatieve en toepassingsgerichte machines en systemen. In de geschiedenis van het bedrijf zijn er veel nieuwe machines ontwikkeld die de industriële verwerking van levensmiddelen aanzienlijk beïnvloed hebben.