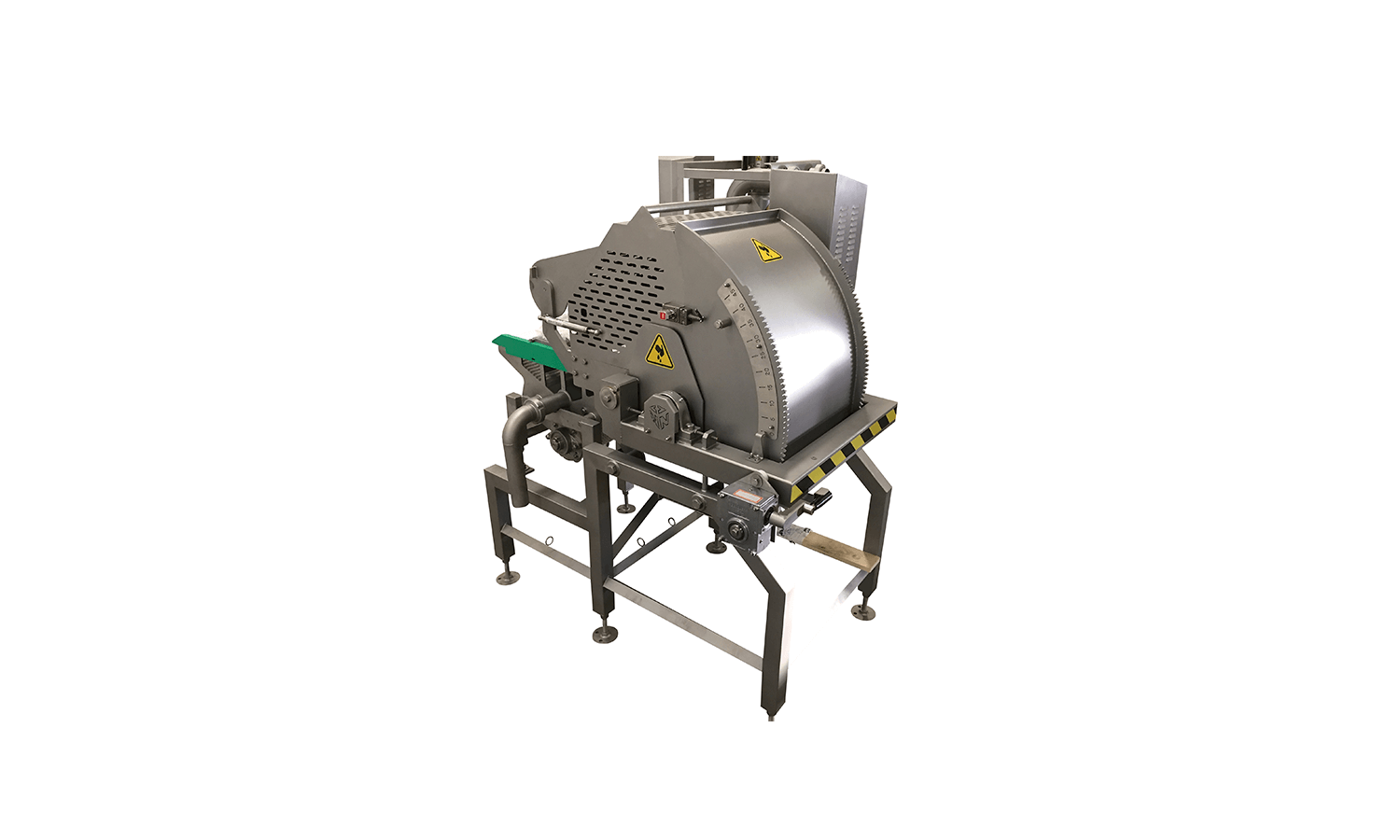

Cutting units

The cutter unit is developed to cut ropes, coming with a continuous flow and cooked by the steam tunnel in pre-determined lengths. When the cooked ropes leave the steel belt, the infeed belt transports the ropes into the cutting unit.

The cutter unit mainly exists of one driven shaft equipped with blades and installed in a framework, all in stainless steel. With a frequency controller the speed of the shaft can be adjusted. By changing the RPM of the shaft, the length of the product can be changed.

The total cutting unit can be adjusted under a variable angle (0°/45°). This means that the chunks can be cut between 90° and 45° angle. The scraper and the counter-knife are always staying in the same position and the cutter-knife is turning without touching the counter-knife. The cutter knife is executed with changeable hardened blades.

ADVANTAGES CUTTER UNIT:

- High speed

- Smooth transfer

- Flexible cutting length

- Cutting angle adjustable

Production line supplier

Selo designs and builds process- and packagingsystems for the food manufacturing, animalfeed, pharmaceutical and non-foodindustries. We offer solutions from A to Z: this makes it possible for us to take care of our projects from the design phase until the installation of the systems. We fully master and take care of all technological, automation, engineering, assembly, installation and after-sales disciplines.

Selo provides both custom and standard solutions.